CarryBot, de Bumerania Robotics, es el primer robot logístico del mundo diseñado para microcentros de distribución. Sus accesorios de transporte versátiles responden a diversas necesidades de transporte de materiales y mejoran considerablemente la eficiencia. CarryBot se adapta rápidamente a entornos cambiantes gracias a la tecnología VSLAM+, que no necesita marcadores ni modificaciones en las instalaciones. Equipado con LiDAR, cámaras de profundidad, sensores de protección contra colisiones y botones de parada de emergencia, CarryBot garantiza una seguridad integral, cumpliendo las normas de seguridad de MFC.

La versatilidad de los accesorios de transporte permite que CarryBot se adapte a las necesidades específicas de cualquier operación. Tanto para partes sueltas como para cajas embaladas, el robot puede completar cada entrega con precisión y cuidado.

Los accesorios se venden por separado, por favor pregunte en el momento de la compra.

CarryBot integra LiDAR, tres cámaras de profundidad y tecnología V-SLAM 2.0. Esta combinación permite que el robot se despliegue sin esfuerzo, navegue por entornos complejos con facilidad y se adapte rápidamente a los cambios en los diseños de producción, garantizando el cumplimiento de las tareas de entrega con mayor seguridad y eficiencia.

Gracias a su capacidad para cumplir necesidades de distribución de cargas de trabajo elevadas, CarryBot puede transportar sin esfuerzo productos a granel, componentes pesados y artículos de inventario de gran tamaño, eliminando el esfuerzo y los riesgos de seguridad asociados a la manipulación manual.

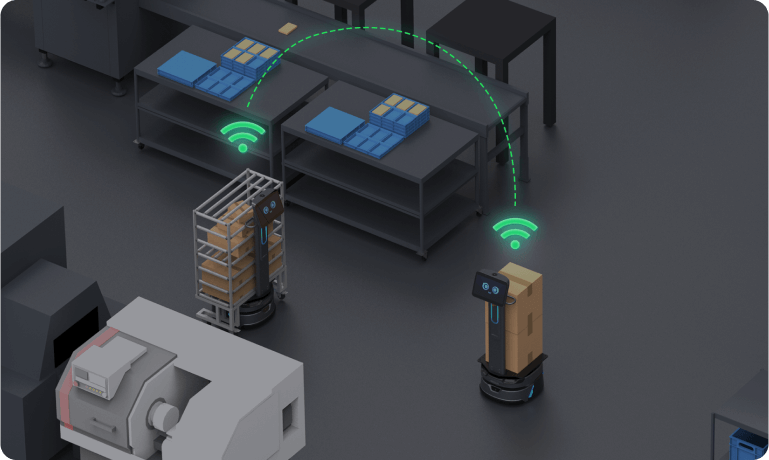

Cuando varios CarryBots que trabajan en el mismo entorno se encuentran en algún punto del recorrido, pueden evitar colisiones de forma autónoma sin necesidad de intervención humana siguiendo el número de robot para establecer prioridad de paso y viajar de forma inteligente.

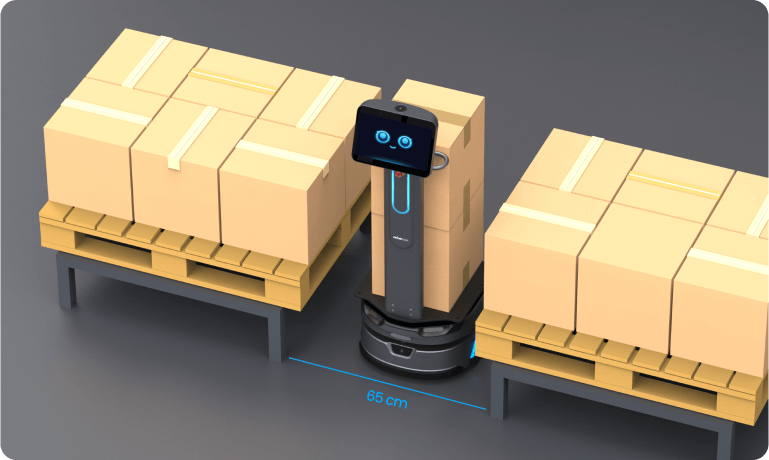

CarryBot se desplaza con eficacia por un espacio libre mínimo de 65 cm, lo que lo convierte en una solución ideal para los espacios reducidos que suelen encontrarse en los microcentros de distribución.

Los robots capaces de superar sin esfuerzo umbrales de 10 mm y surcos de 30 mm pueden adaptarse a diversas condiciones del terreno, reducir los costes de modificación del entorno y mejorar la eficacia y la seguridad del trabajo.

El tiempo de trabajo es de hasta 9 horas con una sola carga (cargas de 100 kg).

Reanuda el trabajo rápidamente: el robot consigue una carga completa en 4,5 horas.

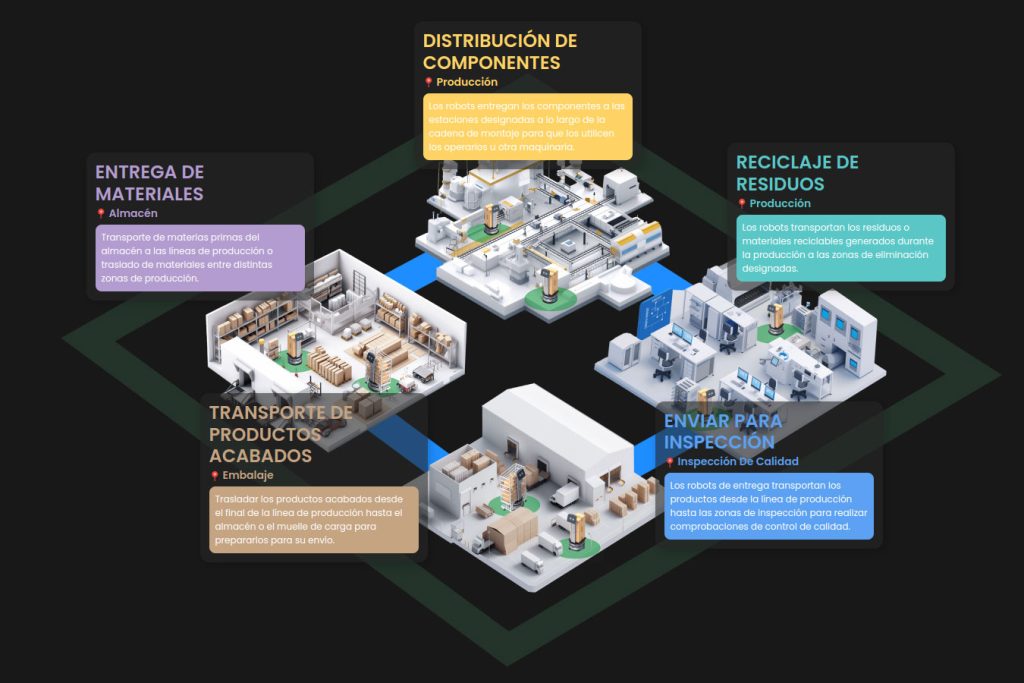

CarryBot puede desempeñar un papel decisivo en diversos flujos de trabajo de la fábrica, ayudando a optimizar los procesos de entrega y mejorando la eficiencia del transporte.

¿Tienes alguna consulta? Rellena el formulario y te llamamos lo antes posible.